Avoid These Common Welding Defects

Since welding is an art and a science, many things can and do go wrong. Novice welders often find that they create welds that have flaws. It's the mark of a good craftsman to produce welds that are strong and clean and that hold up over time. Don't accept work that has welding flaws. Here are a few things to look out for when your welder finishes a job.

1. Cracks There are actually quite a few ways cracks can occur in a weld. A welder might begin the arc weld outside the weld groove, an act that causes the outside metal to crack as it cools down. A crack might appear along the length of a weld because the welder created a too-small weld bead. A crack may appear at the beginning of a weld bead because of increased moisture in the metal. Most of the time, cracks can be repaired only by more welding. The open spaces in the cracks need to be completely filled by new welding material so they don't weaken the entire piece.

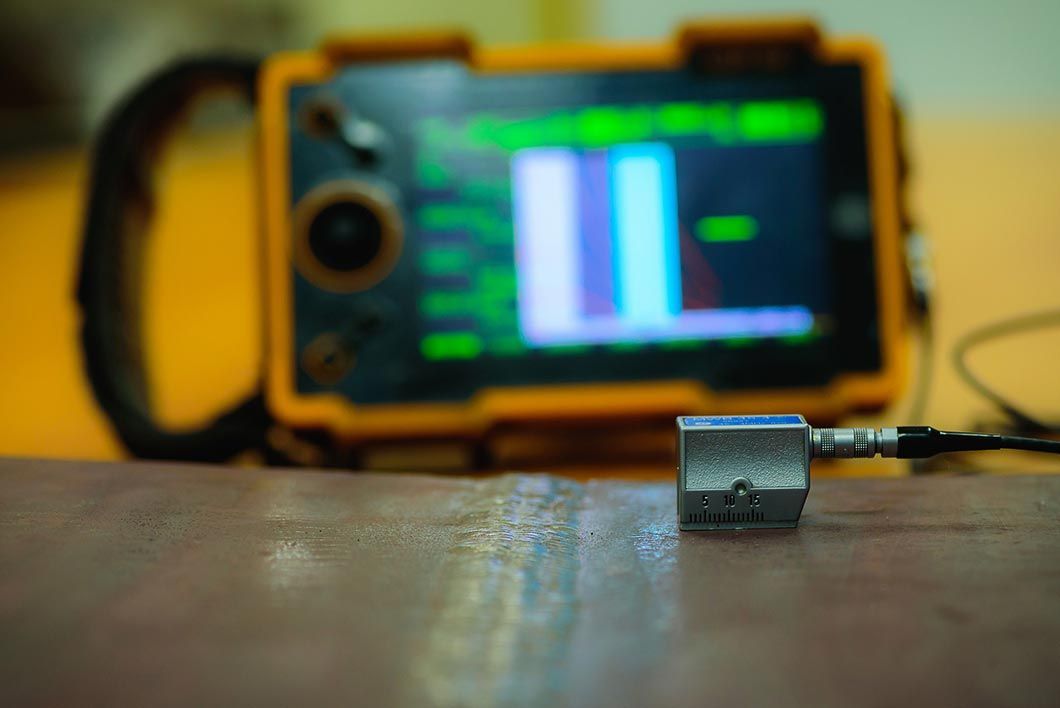

2. Incomplete Penetration In this defect, the filler metal does not completely fill in the gap of the base metal, leaving a gap or crack. It's difficult to see this defect because the problem is inside the weld, but the weld will fail if you apply too much pressure or force. This defect can occasionally be repaired by one’s removing the weld and starting over. But sometimes the project must be thrown away and restarted with a new weld.

3. Lack of Fusion This defect occurs when the filler metal, or weld bead, doesn't completely fuse to the base metal. Most of the time this defect occurs because the welder holds the filler rods or electrode at the wrong angle, creating a weld that overlaps the side or top of a weld. Most of the time this problem can be solved only in the moment, when the welder notices an issue.

4. Distortion Distortion refers to the warping of metal due to heating and cooling. Since welding involves applying heat to the base metal, distortions are always a possibility. The base metal can be distorted a number of different ways: it can shrink, bend or curve, stretch, angle, or change direction. Since distortions affect the shape of the final piece, they often cannot be corrected, meaning the project must be restarted.

5. Inclusions Inclusions are substances that get trapped within the weld. The weld should only contain the weld material. Anything else can cause weakness in the weld. Gas inclusions occur when there is too much moisture or sulfur content in the metal. Slag inclusions happen when the waste material from the weld, the slag, get stuck in the weld. Welders can prevent inclusions during the weld by cleaning off the material in between passes. Once the project is finished, the only way to get rid of an inclusion is to replace the weld or start the project over.

6. Undercutting Undercutting happens when the heat of the weld burns the base metal away at the toe, or side, of the weld. Essentially, there is a divot on one or both sides of the weld bead, and this divot weakens the base metal. If the base metal burns away too much, the structural integrity of the piece will be faulty, and the whole project must start over. Most often, undercutting occurs because welders use too much heat.

7. Spatter Spatter refers to the particles of metal that fly off the weld and stick to the workpiece. Spatter occurs during every weld — no level of experience or skill will prevent spatter. However, experts apply an anti-spatter compound to the base metal or periodically scrape the base metal off. Spatter usually doesn't affect the integrity of a weld unless it becomes an inclusion. You don't want your welding projects to be plagued by these defects. Call a professional welder to complete your welding project and get exactly the results you hoped for.